Our approach to sustainability these days is inspired by the concept of circularity — swapping out the linear “take, make and waste” approach for a closed-loop system that recycles and reuses the same resources.

Put simply, circularity in fashion means designing products so that they can be used more, made to be made again, and are constructed with safe, recyclable and renewable inputs.

You can see that concept come to life in our approach to water.

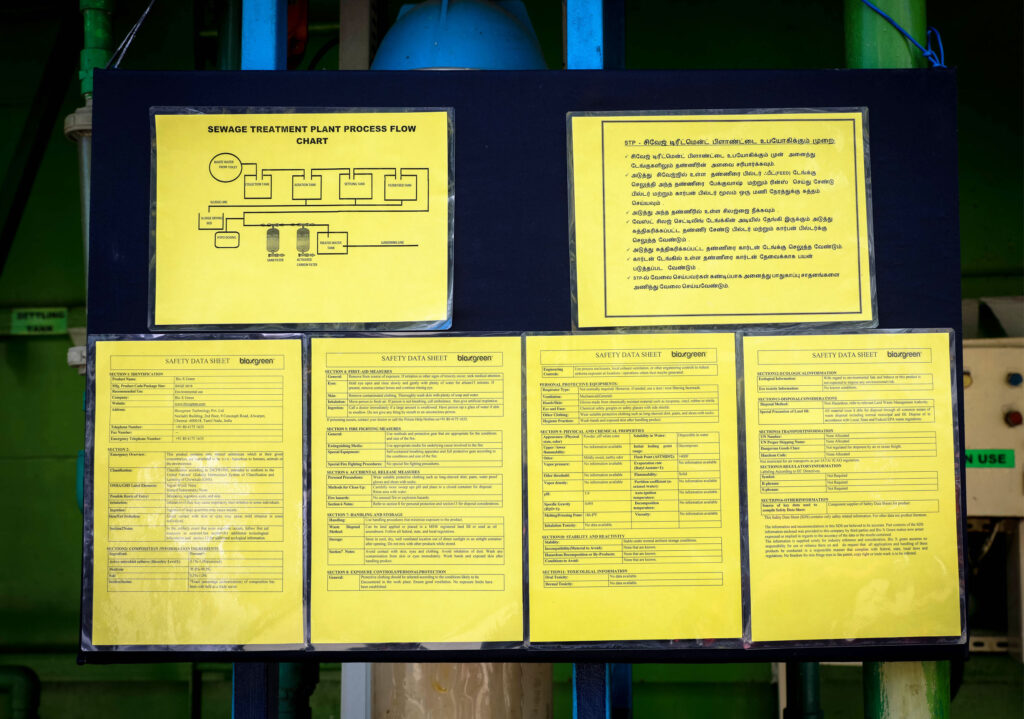

Our Padalam factory is equipped to recycle 55,000 litres of water per day through sewage treatment plants.

“Water is one of the most crucial impacts embedded in your clothing because it is consumed throughout the value chain. “To effectively address these impacts, we must ensure that production, supply chain practices and technologies ensure the effective use of resources, like water.”

The stakes could not be higher. Today, over two billion people live in water-stressed areas around the world — and by 2050, that number will grow to include more than half the world’s population if no action is taken, according to the United Nations.

Driven by that knowledge, we’ve set ourselves an ambitious target to cut our water use for manufacturing in highly stressed areas and to achieve the same, we joined the BCI – Better Cotton Initiative, where we follow their lead in taking this challenge by doing what we can from our end. Read more about BCI’s initiatives here.

Water saving taps were installed in the canteen and new washrooms – enabling water saving by controlling the water flow from 6 litres/minute to 3 litres/minute from each tap installed.

A volume of 85,000 litres of water has been harvested through Rain Water Harvesting.

While we know that there’s no single, one-size-fits all solution, we’re confident that the path forward isn’t a straight line — it’s circular.