Evolv’s manufacturing unit is equipped with the latest IoT-enabled machines to maximize production efficiency and to keep track of production at every step of the process.

With the help of JaNets Juki advanced network system and Brother IoT – grasping the work progress in the line on a real-time basis, machine’s operation status (operation rate, failure rate) and detection of the sewing machine errors improves quality and helps in maintaining efficiency.

IoT system enables workers to view the split between operating time and non-operating time of all the machines in the factory.

With the production data displayed on the big screen, each operator can set their goal for the day and keep everything organized.

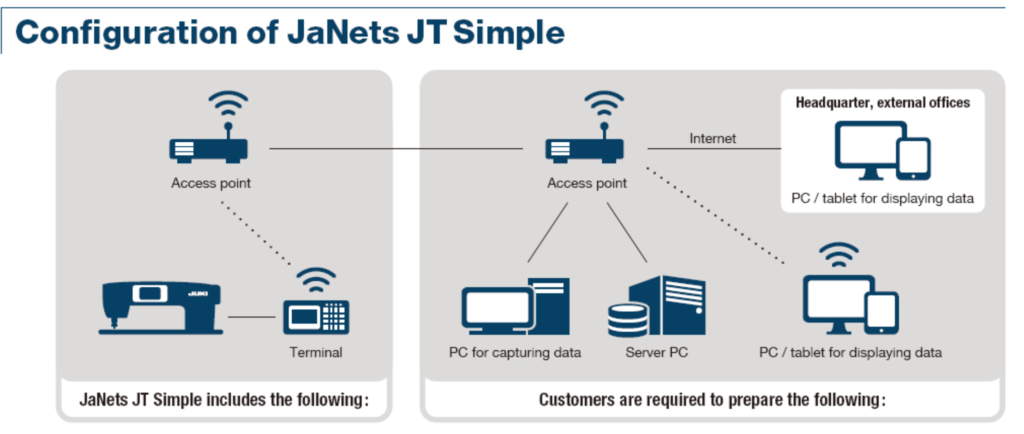

JaNets JT Simple is the machine operation management system that can receive the operation data and quantity of output of the sewing machine transferred from the terminal installed on each sewing machine for monitoring. With the use of this system, on-time data capturing happens efficiently and productivity increases significantly.

“IoT has become a crucial part of Evolv’s manufacturing process. With all these constructive data outputs generated throughout the production floor every operational minute, the system generates a pitch diagram, which helps us in evaluating BPT, UCL and LCL. This helps us understand the true efficiency of the production line and keep the delivery timelines on track.”

Know more about the JaNet technology on their website.

Know more about Brother IoT here.